Profiles : http://theprofilepaintshop.blogspot.com.tr/

At 09:30 hours on 22nd July, a Me.109G-14 was shot down by light A.A. fire near Fontenay-le-Poesnel, making a good belly-landing in a grass field, only 800 yards away from the enemy lines. An obstruction post was hit before the aircraft came to rest, and severe damage was done to the starboard mainplane.

This aircraft is the first of its sub-type to be identified, and presents a number of interesting features. At the present stage of the war the most interesting are, perhaps, those which point to the very short time elapsing between its leaving the factory and its destruction. Technically the aircraft is of interest as it was carrying a special tank containing a fluid known to the Germans as `MW50'. The power boosting qualities of this fluid will be described under the heading of 'Engine' below.

Apart from the fitting of this tank and the installation of FuG 16 ZY, this aircraft is almost identical with the Me.109 G-6/U2

Identification Markings

+ 7 (black outlined yellow)

Call sign: VW+HO

Works No.: 413601

Maker: Mcu. (ed.note: code for Erla- Leipzig)

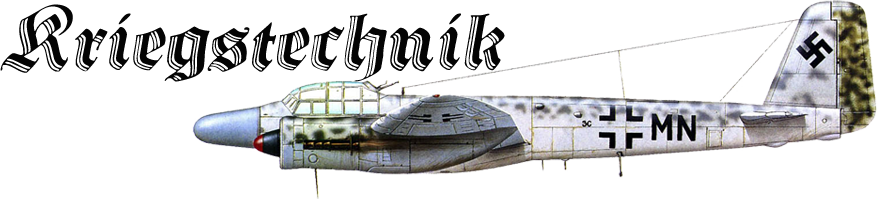

Camouflage

Light and dark grey upper surfaces, light blue lower surfaces. The lower half of the fuselage sides mottled with patches of grey and green. The spinner is black with a white spiral.

Engine

DB605 A-1 Tp

Maker: hsr. (ed.note: code for Henschel- Kassel)

No.01104968

Painted on the crankcase cover is: 605 A/M

This engine has the normal small supercharger and both engine bearers are of light alloy. C-3 (100 octane) fuel is used but additional power for short periods is obtained from an apparatus known as the `MW 50', in conjunction with a boost pressure of 1.7 ata (equals British boost of +9.5). This is a system of delivering methanol and water to the eye of the supercharger from a light alloy tank (probably of 35 gallon capacity) situated behind the normal fuel tank. The methanol tank is built in during manufacture and cannot be removed for servicing. The pressure side of the supercharger is tapped by a pipe which leads via a relief valve to the top of the light alloy tank, so supplying the pressure for feeding the mixture to the engine. A supply pipeline from the tank to the eye of the supercharger carries the methanol and water mixture. In this pipeline there is a solenoid operated valve and a pressure gauge connection. A switch on the port side of the cockpit beading, marked `MW 50' operates the solenoid valve and is a simple On/Off switch. The pressure gauge, reading from 0 to 3 kgslsq. cm. (0 to 42 lb./sq. in.) is located lower down on the port side of the cockpit. The actual pressure used is between 1.2 and 1.8 kgs./sq. cm. (17 lb/sq. in. -25.6).

It is estimated that the power at sea level, when using `MW 50' with a 1.7 ata boost (equals British boost of +9.5) and 2,800 r.p.m. is 1,770 h.p. The D.B. 605A without the `MW 50' develops 1,450 h.p. at 1.42 ata boost (equals British boost of +5.5) and 2,800 r.p.m. at sea level.

The boost gauge is marked with a series of red lines on the glass, as follows: d opposite 1.02 ata. = British -0.2 30 opposite 1.3 ata = British +3.8

3 opposite 1.42 ata = British + 5.5 MW 50 opposite 1.7 ata = British +9.5

The figures on the glass refer to the time in minutes for the use of the respective boost pressures, the d8 meaning maximum continuous. The rev. counter is also marked opposite the respective r.p.m.

The sparking plugs are of a type not previously fitted to D.B. 605 engines but they were found recently in the Jumo 213. They are Bosch D.W. 250 E.T. (10/1) and are stamped 5Z (this is the manufacturer's date code and indicates May, 1944).

The magneto is marked 9/4040E, Serial No. 453864. Manufacturer cxo under license from L.Z.U.

The flange bears the following markings: BA 13402 cxo 4Z.

Armament

1 x MG151 20 mm. calibre, firing through propeller hub.

2 x MG131 over the engine.

Loading order 20 mm. gun- 1 AP/I, - 1 HE/I/T (S.D.)(M. Geschoss) repeating. This order changed later in the belt to- 1 AP/T - 1 I/T, - 2 HE/I/T (S.D.)(M. Geschoss) repeating.

Loading order for 13 mm. guns- 1 AP/T, - 1 HE/T repeating. Nearly all tracer rounds were night trace, although the aircraft was on a daylight operation.

None of the guns had been fired and it was found that the ammunition tanks had not been completely filled.

Tank capacity Rounds carried

20 mm 200 per gun 150

13 mm 300 per gun 275

The Revi 16B gunsight was used.

Armour

Pilot's bullet-resisting glass screen. The cockpit cover was jettisoned before the crash and could not be recovered. No other armour is fitted to this aircraft.

Internal equipment

Radio: FuG 16 ZY fitted. 1' aerial mounted on underside of the port wing, 7 ft. 2 in. from wing root and 9 in. back from the leading edge. The aerial itself, which consists of a tapering streamlined light alloy tube 24 1/2 in. long with a semi-flexible stranded wire tip 12 1/2 in. long projects through a 'Plexiglass'

disc set in the wing surface. The aerial matching unit, A.A.G. 16 E-3, Gerat No. 124-1508 E-1. Anfz. Ln. 27185-6 Manufacturer dmr., was mounted immediately above the aerial inside the wing. A single concentric aerial feeder, marked E143, connected the matching unit to the set via a small box, mounted on the base panel, immediately above it. It was not possible to examine this box without removing it, but it is believed to contain a relay. The FuG 16 ZY itself has no aerial ammeter fitted, a blanking plate covering the vacant spot. Four spot frequency selectors were fitted on both receiver and transmitter. The dick stop settings were:

Receiver: - I- blank II- 41.85 39.7 40.9

Transmitter: - I- blank II- 41.85 39 40.9

When found both units were on 40.9 mc/s.

No Z.V.G.16, navigational unit, was installed. Bracket for FuG 25, but no units fitted. The four-spot frequency switch in the cockpit was mounted on the lower right of the instrument panel.

The layout of the instruments has not changed, but they were mounted in a wooden panel. Compared with the Me.109 G-6/U2 the following items had been moved:

Battery 24 V. 7.5 amp - from the rear of the fuselage to a point immediately behind the pilot's head. (From the servicing point of view, the battery is badly placed, as it is wedged between the top of the petrol tank and the top of the fuselage, and is extremely difficult to take out.)

The 'taster compass - has been moved from the position immediately behind the petrol tank to its original place at the rear of the fuselage.

Oxygen bottles - These are now in the port wing instead of in the rear of the fuselage.

Tankage - The petrol tank was non-self-=sealing, being made of light alloy. It appeared to be protected only by a box of 7-ply wood. On the other hand, the small priming fuel tank which is fitted in the upper part of the fuselage on the starboard side, some 4 ft. forward of the base of the fin, is self-sealing.

Points of Interest

The two hand wheels controlling the landing flaps and the tail incidence, as well as the FuG 25 mounting panel, were made of ply-wood.

It is usual for both sides of the landing wheels and oleo leg fairing to have coats of finished paint, but on this aircraft the inner sides were finished in a red primer coat only.

There was wiring for wing guns and also the mountings for ammunition tanks, so that the two wing M.G. 151/20's could rapidly be fitted to this sub-type•

The wiring in this aircraft is almost entirely unscreened.

In previous Me.109's examined, the breech of the gun firing through the propeller hub has projected into the cockpit, but has not been covered. In this machine, however, there is a neat fairing round the breech, and on it are painted instructions concerning engine revs. for delivery flights or test flights after an engine change. These state: -

(1) On deliver flights or test flights after an engine change, after take-off do not exceed 2,100 r.p.m. and 1.05 ata of boost. If possible duration of flight should not exceed one hour. Watch oil pressure.

(2) For the first five hours, if possible do not exceed 2.300 r.p.m. and 1.15 ata boost.

(3) For the second five hours, if possible do not exceed 2.600 r.p.m. and 1.30 ata boost

(4) After ten hours, the aircraft may be flown if necessary without limitations other than those laid down in current instructions.

In conclusion, tribute must be paid to the excellent co-operation of the salvage party, the Army, and the Royal Navy, which enabled this aircraft to be delivered to R.A.E Farnborough in less than three days after it was shot down in Normandy